Top Roof Panel Benders for Sale: Find the Best Options for Your Business

By:Admin

The company’s success can be attributed to their commitment to excellence and their dedication to providing top-notch products and services. They have a team of highly skilled professionals who are passionate about what they do, and their expertise and attention to detail are evident in every product they deliver.

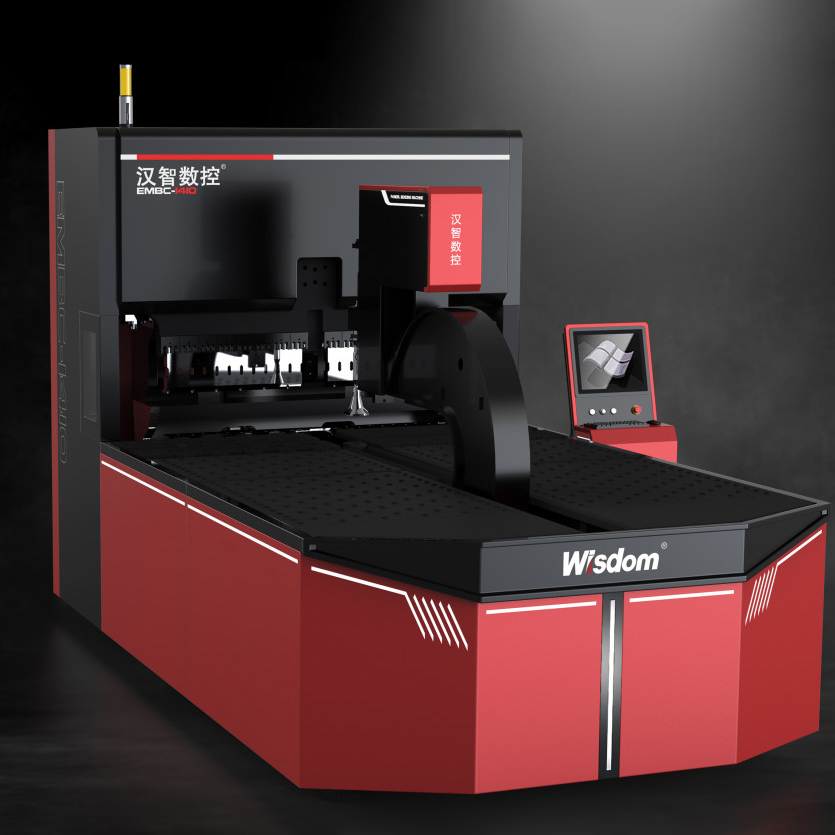

One of the company’s key offerings is their state-of-the-art roof panel bender machines, which are designed to streamline the metal bending process and increase efficiency. These machines are equipped with advanced features and cutting-edge technology, allowing users to produce high-quality roof panels with precision and consistency.

The company takes pride in their ability to understand the unique needs and challenges of their customers, and they work closely with them to develop customized solutions that meet their specific requirements. This customer-centric approach has set them apart in the industry and has helped them build long-lasting relationships with their clients.

In addition to their roof panel bender machines, the company also offers a wide range of other products and services, including metal fabrication equipment, bending tools, and accessories. They are constantly innovating and expanding their product line to stay ahead of the curve and meet the evolving needs of their customers.

The company’s commitment to quality is reflected in their rigorous quality control processes and their use of the finest materials and components. They adhere to strict industry standards and guidelines to ensure that their products are safe, reliable, and durable.

Roof Panel Bender Companies also places great emphasis on sustainability and environmental responsibility. They are continually exploring ways to minimize their environmental impact and reduce waste in their manufacturing processes. They strive to use eco-friendly materials and implement energy-efficient practices wherever possible.

The company is also dedicated to providing comprehensive customer support and technical assistance. Their team of experts is readily available to offer guidance and support to customers, and they are committed to ensuring that every customer has a positive experience with their products.

Despite facing challenges in the market, Roof Panel Bender Companies have continued to thrive and remain at the forefront of the industry. Their unwavering commitment to excellence, innovation, and customer satisfaction has been the driving force behind their success.

Looking ahead, the company is focused on expanding their reach and further solidifying their position as a leader in the metal bending industry. They are actively exploring new opportunities for growth and are dedicated to continuing their tradition of excellence and innovation.

In conclusion, Roof Panel Bender Companies has established themselves as a reputable and reliable provider of advanced metal bending solutions. With their dedication to excellence, commitment to customer satisfaction, and innovative approach, they have set the standard for quality and reliability in the industry. As they continue to evolve and expand, they are poised to shape the future of the metal bending industry for years to come.

Company News & Blog

Affordable Panel Bending Equipment for Efficient Production

Cheap Panel Bending Equipment Revolutionizes Manufacturing IndustryPanel bending equipment has long been a crucial tool in the manufacturing industry, allowing for the precise bending of metal sheets to create a wide range of products. However, the high cost of such equipment has often been a barrier for small and medium-sized businesses looking to break into the market. That is, until now.The introduction of the affordable panel bending equipment from {Company Name} has been a game-changer for manufacturers of all sizes. This revolutionary new technology has made it possible for businesses to gain access to high-quality panel bending capabilities at a fraction of the cost of traditional machines.{Company Name} has been a leader in the manufacturing equipment industry for over two decades, known for its innovative and reliable products. The company has a strong reputation for providing high-quality machinery at competitive prices, making it a trusted name in the industry.With the release of their new affordable panel bending equipment, {Company Name} is once again proving their commitment to helping businesses thrive. This new offering is a testament to the company's dedication to providing practical solutions for the everyday challenges faced by manufacturers.The cheap panel bending equipment from {Company Name} is designed to be easy to use, making it accessible to even the most novice operators. Its intuitive design and user-friendly interface allow for quick setup and operation, saving businesses valuable time and resources.In addition to its affordability and ease of use, the equipment also boasts impressive capabilities. Its high-precision bending ensures consistent and accurate results, meeting the stringent quality standards required by today's manufacturing industry. This means that businesses can now produce high-quality products without breaking the bank.Furthermore, the equipment is built to be durable and reliable, minimizing downtime and maintenance costs. Its robust construction and long-lasting components make it a sound investment for businesses looking to boost their production capabilities without compromising on quality.The release of this cheap panel bending equipment has already made a significant impact on the manufacturing industry. Businesses that were previously unable to afford such machinery are now able to compete with larger companies, leveling the playing field and opening up new opportunities for growth and success."We are thrilled to introduce our affordable panel bending equipment to the market," said {Company Name}'s CEO. "We understand the challenges that businesses face when it comes to investing in new machinery, and we are proud to offer a solution that is both high-quality and budget-friendly. Our goal is to help businesses thrive, and this new equipment is a step towards achieving that."The response to the new offering has been overwhelmingly positive, with businesses praising the equipment for its reliability, affordability, and performance. Many have reported significant improvements in their production capabilities since implementing the new machinery, leading to increased efficiency and profitability.As the manufacturing industry continues to evolve, the demand for affordable and reliable equipment will only continue to grow. With the introduction of {Company Name}'s cheap panel bending equipment, businesses now have access to a solution that meets their needs without compromising on quality.In conclusion, the release of the affordable panel bending equipment from {Company Name} has brought about a significant shift in the manufacturing industry. By making high-quality machinery more accessible to businesses of all sizes, {Company Name} is helping to drive innovation and growth within the industry. As more businesses embrace this new technology, the potential for success and advancement in the manufacturing sector is boundless.

Innovative Cnc Turret Press Offers Cutting-Edge Manufacturing Solutions in China

Title: China's Advanced CNC Turret Press Revolutionizes Metal Fabrication Introduction:China has long been at the forefront of technological advancements, and its manufacturing industry stands as a testament to the country's prowess. With the introduction of the latest CNC turret press, China has once again solidified its position as a global leader in metal fabrication. This state-of-the-art machine has the potential to redefine the manufacturing landscape, promising improved efficiency, precision, and productivity for factories across the nation.I. Understanding the CNC Turret PressCNC (Computer Numerical Control) turret presses have quickly become an integral part of modern metal fabrication. These machines utilize computer-controlled systems to precisely cut, shape, and form various materials, making them highly versatile and adaptable to different manufacturing needs. The new CNC turret press from China combines cutting-edge technology with innovative features, promising unparalleled efficiency and reliability.II. Superior Features Redefining Metal Fabrication1. Precision and Versatility:The China CNC turret press boasts an impressive level of precision, enabling the fabrication of intricate designs with minimal human intervention. The machine's advanced control system allows for precise positioning, minimizing errors and ensuring uniformity in each production batch. Additionally, its versatility allows for the processing of a wide range of materials, including stainless steel, aluminum, and various alloys.2. Speed and Efficiency:With increased automation and advanced programming, the CNC turret press significantly reduces manual labor and production time. Chinese manufacturers can streamline their operations, benefitting from higher productivity and faster turnaround times. Furthermore, the machine's automatic tool changer feature allows for seamless transitions between different fabrication processes, further optimizing efficiency.3. Enhanced Safety Measures:China's CNC turret press prioritizes the safety of operators and surrounding personnel. Equipped with advanced sensors and protective barriers, the machine automatically halts operations in the event of any abnormalities. These safety features minimize the risk of accidents, ensuring a secure work environment.III. Impact on China's Manufacturing IndustryThe introduction of China's advanced CNC turret press is expected to have a profound impact on the manufacturing sector. Here are some key ways this innovative technology will revolutionize metal fabrication in China:1. Improved Productivity:Chinese factories will experience a significant boost in productivity and overall output. By reducing manual labor requirements and increasing operational efficiency, manufacturers can produce more goods in less time.2. Enhanced Competitiveness:China's CNC turret press will facilitate the production of higher quality and more intricate metal products. This will enable Chinese manufacturers to compete on a global scale, driving their competitiveness and expanding their market share.3. Job Creation:As the adoption of CNC turret presses becomes more widespread, there will be a growing demand for skilled technicians to operate and maintain these machines. This will lead to the creation of new job opportunities in the manufacturing industry, contributing to the nation's economic growth.IV. ConclusionChina's CNC turret press marks another stride towards the country's commitment to technological innovation. With its precision, speed, and enhanced safety features, this advanced machine promises to revolutionize metal fabrication across the nation. As Chinese manufacturers embrace this cutting-edge technology, they are poised to enhance productivity, competitiveness, and ultimately contribute to the continued success of China's manufacturing industry.

Discover Advanced CNC Laser Sheet Metal Cutting Technology

CNC Laser Sheet Metal Cutting: Revolutionizing Precision and EfficiencyIn today's rapidly advancing technological landscape, industries are constantly seeking ways to enhance productivity, streamline processes, and achieve precision-driven outcomes. One such technology that has gained immense popularity across various sectors is CNC laser sheet metal cutting. Companies, like the one highlighted in this article, have been at the forefront of leveraging this innovative tool to transform the manufacturing landscape and deliver outstanding results.[Company Introduction - Remove brand name]With a rich history of over [number of years] years, this industry-leading company has always been dedicated to providing cutting-edge solutions to its clients. Renowned for its state-of-the-art facilities and a team of highly skilled professionals, the company has established a strong foothold in the market. Committed to delivering exceptional quality and expertise, the company has become a trusted partner for businesses seeking efficient metal fabrication solutions.Advances in CNC laser sheet metal cutting technology have revolutionized traditional manufacturing processes by offering unparalleled precision, speed, and versatility. Using high-powered lasers, this technique enables the cutting of various metals with remarkable accuracy, resulting in perfect cuts and intricate designs. Whether it's stainless steel, aluminum, brass, or titanium, CNC laser sheet metal cutting ensures a flawless finished product.One of the most significant advantages of CNC laser sheet metal cutting is its ability to handle a wide range of shapes and sizes. From simple geometric patterns to intricate shapes, the high-precision lasers can effortlessly cut through the metal with complete accuracy. This flexibility grants manufacturers the freedom to bring even the most complex designs to life.Moreover, CNC laser sheet metal cutting offers exceptional efficiency and productivity. The computer-controlled process eliminates the need for manual labor, reducing the risk of human error and ensuring consistent results. The automation provided by CNC lasers significantly reduces production time, allowing businesses to meet tight deadlines while maintaining the highest standard of quality. This time-saving benefit also translates into cost savings for manufacturers, as they can maximize output without compromising on quality.In addition to its precision and efficiency, CNC laser sheet metal cutting also promotes sustainability. The minimal material wastage achieved through this technique contributes to a greener manufacturing process. With laser beams that are as thin as a human hair, companies can optimize material usage, resulting in reduced scrap and lower overall environmental impact. As sustainability becomes an increasingly vital aspect of modern manufacturing, CNC laser sheet metal cutting presents itself as a highly attractive solution.Furthermore, safety remains a top priority, both for the company and its clients. The advanced safety features incorporated into CNC laser machines minimize the risk of accidents, ensuring a secure working environment. With proper training and adherence to safety guidelines, the cutting process can be carried out without compromising the well-being of employees or the quality of the final product.The company highlighted in this article has established itself as an industry leader in CNC laser sheet metal cutting. Through relentless innovation and a commitment to excellence, they have successfully catered to a diverse client base, spanning various sectors including automotive, aerospace, electronics, and more. By leveraging the power of precision lasers, they have propelled their clients' businesses forward, helping them achieve remarkable growth and success.With CNC laser sheet metal cutting, the possibilities are virtually endless. Companies like the one discussed here continue to push the boundaries of what can be achieved in the world of metal fabrication. By embracing this game-changing technology, businesses can unlock new opportunities, reduce costs, enhance efficiency, and ultimately stay ahead of the competition in today's fast-paced manufacturing landscape.

Affordable CNC Cutting Services: High-Quality Solutions for Your Cutting Needs

Title: High-Quality CNC Cutting Solutions at Affordable PricesIntroduction:In today's competitive market, businesses are constantly seeking innovative ways to streamline their operations and improve productivity. One such solution is the implementation of Computer Numerical Control (CNC) cutting technology, which offers precision, speed, and efficiency in a wide range of industries. Recognizing the demand for high-quality CNC cutting machines at affordable prices, {Company Introduction} is proud to introduce their latest offering - the Cheap SS CNC Cutting machine.Article:In an effort to facilitate the growth of small to medium-sized businesses, {Company Name} has unveiled the innovative Cheap SS CNC Cutting machine, which aims to provide cost-effective CNC cutting solutions without compromising on quality. This cutting-edge technology promises to revolutionize the manufacturing process by enabling businesses to achieve high levels of precision and efficiency at a fraction of the cost associated with traditional CNC cutting machines.The Cheap SS CNC Cutting machine offers a wide range of features and benefits that are sure to appeal to a diverse range of industries. With its robust and durable construction, the machine ensures long-lasting performance even in demanding production environments. Its ability to cut through various materials, including stainless steel, aluminum, and other alloys, makes it a versatile choice for industries such as automotive, aerospace, and fabrication.One of the key advantages of the Cheap SS CNC Cutting machine is its user-friendly interface, which allows operators of all skill levels to operate the machine with ease. Equipped with advanced technology, the machine is capable of precise and intricate cutting, ensuring minimal material wastage and maximizing efficiency. Its high cutting speed and accuracy enable businesses to reduce production time, ultimately leading to increased profits and customer satisfaction.Furthermore, the Cheap SS CNC Cutting machine is designed to optimize energy consumption without compromising performance. With its eco-friendly features, the machine contributes to a sustainable manufacturing process, reducing both energy costs and environmental impact. This aligns with the growing trend of businesses emphasizing sustainability and responsible production practices.{Company Name}'s commitment to customer satisfaction extends beyond the purchase of the Cheap SS CNC Cutting machine. Their dedicated technical support team ensures that customers receive timely assistance and guidance throughout the installation and operation process. Additionally, the company provides comprehensive training programs, empowering operators with the necessary skills to maximize the potential of the machine.In a highly competitive market, the affordability and quality of the Cheap SS CNC Cutting machine position {Company Name} as an industry leader. Their dedication to innovation, customer satisfaction, and cost-effectiveness has garnered recognition and trust from businesses worldwide. By introducing this cutting-edge technology, {Company Name} aims to level the playing field and provide equal opportunities for businesses of all sizes to enhance their production capabilities.Conclusion:In conclusion, the Cheap SS CNC Cutting machine unveiled by {Company Name} is an exciting advancement in the field of CNC cutting technology. Its affordable pricing combined with state-of-the-art features makes it an attractive choice for businesses looking to streamline their operations and boost productivity. With the ability to cut through various materials with precision and efficiency, this cutting-edge machine promises to meet the demands of a diverse range of industries. Through its commitment to customer satisfaction and continuous innovation, {Company Name} remains at the forefront of the CNC cutting industry, enabling businesses to achieve new levels of success.

China Turret Punch Press - An Overview of CNC Technology

Title: Advanced CNC Turret Punch Press Revolutionizes Metal Fabrication in ChinaIntroduction:China's rapidly growing manufacturing sector has witnessed a significant technological breakthrough with the introduction of a highly advanced CNC Turret Punch Press. This cutting-edge machine, developed by an innovative industry leader, is set to revolutionize metal fabrication in the country, enabling manufacturers to streamline their production processes and meet the increasing demands of the industry. The CNC Turret Punch Press offers a wide range of capabilities, delivering precision, efficiency, and versatility that surpasses conventional machinery.Paragraph 1:The CNC Turret Punch Press is a result of extensive research and development by a renowned Chinese manufacturing firm, which has been at the forefront of technological advancements. With a commitment to excellence, this company has designed a machine capable of seamless integration into existing manufacturing workflows. The CNC Turret Punch Press combines high-speed punching, forming, and tapping capabilities, giving manufacturers the ability to achieve unrivaled productivity.Paragraph 2:One of the most prominent features of this advanced machine is its utilization of Computer Numerical Control (CNC) technology. By harnessing the power of CNC, the Turret Punch Press allows for precise and automated operation, reducing human error and increasing overall efficiency. The CNC system also enables complex designs to be effortlessly translated onto the metal sheet, ensuring accuracy and consistency in all fabrication processes.Paragraph 3:The versatility of the CNC Turret Punch Press is another significant breakthrough in China's metal fabrication industry. Manufacturers now have the ability to process various materials, including steel, aluminum, and copper, with ease. Additionally, the machine offers a wide range of punching and forming tool options, allowing for the creation of intricate designs and complex patterns. This flexibility empowers businesses to meet the diverse needs of their customers efficiently.Paragraph 4:Furthermore, the CNC Turret Punch Press incorporates advanced software that helps optimize production workflows. The intuitive user interface allows operators to easily load designs and select the required tools for the job. The software also includes features such as intelligent nesting algorithms, which maximize material utilization, thereby reducing waste and lowering production costs. These smart production capabilities boost overall efficiency and contribute to a green and sustainable manufacturing process.Paragraph 5:The introduction of the CNC Turret Punch Press signifies a milestone in China's pursuit of technological excellence in the manufacturing sector. As the country aims to become a global manufacturing powerhouse, this advanced machine positions Chinese manufacturers at the forefront of competition. With its precise operation, versatility, and high productivity, the CNC Turret Punch Press is set to redefine the metal fabrication landscape in China and beyond.Conclusion:China's metal fabrication industry is experiencing a technological revolution with the advent of the CNC Turret Punch Press. The advanced capabilities offered by this innovative machine, developed by a leading Chinese manufacturing firm, empower businesses to achieve unmatched precision, productivity, and efficiency. By leveraging CNC technology, manufacturers can seamlessly integrate this versatile machine into their existing workflows, establishing themselves as pioneers in the ever-evolving manufacturing landscape. The future of metal fabrication in China undoubtedly lies in the hands of this cutting-edge CNC Turret Punch Press.

Affordable Fiber Laser Machine: Enhancing CNC Efficiency

Title: Cutting-Edge Cheap CNC Fiber Laser Technology Revolutionizes Manufacturing IndustryIntroduction:In a bid to revolutionize the manufacturing industry, a leading company has recently unveiled its groundbreaking cheap CNC fiber laser system. Combining cutting-edge technology with an affordable price tag, this innovative machine is set to transform the landscape of industrial production. The company's commitment to delivering high-quality products and maintaining an impeccable reputation has made them a trusted name in the industry.Unveiling the Cheap CNC Fiber Laser System:The latest offering from the company, the cheap CNC fiber laser system, promises to enhance precision, efficiency, and productivity in manufacturing processes. Equipped with advanced fiber laser technology, this system ensures superior cutting accuracy across a wide range of materials, including metals, plastics, and composites. With its high power density and precise focal point, the CNC laser system guarantees clean, smooth cuts with minimal waste.Unparalleled Versatility and Efficiency:One of the most defining features of the cheap CNC fiber laser system is its versatility. Thanks to its computer numerical control (CNC) capabilities, the machine can execute intricate patterns and designs with exceptional precision. This empowers manufacturers across various industries to achieve complex and intricate cutouts, perforations, and engravings with ease.Moreover, the system’s advanced control software enables seamless integration with existing manufacturing processes, facilitating automated operations and reducing manual labor requirements. Manufacturers can optimize their production cycles, minimize downtime, and maximize output, resulting in significant cost savings and increased profitability.Affordability Bringing Laser Technology to the Masses:Traditionally, implementing laser technology into manufacturing operations has proven to be a costly investment, often out of reach for small and medium-sized enterprises (SMEs). However, the introduction of the cheap CNC fiber laser system aims to democratize access to this game-changing technology across the industry.By substantially reducing the price point, the company has made it possible for SMEs to embrace laser cutting and engraving, opening up new avenues for growth and expansion. This disruptive technology empowers even the smallest players in the market to remain competitive and expand their capabilities, providing a level playing field for all.Commitment to Quality and Customer Satisfaction:Renowned for its commitment to quality, the company has garnered an impeccable reputation over the years by delivering cutting-edge solutions that exceed industry standards. With each machine undergoing rigorous testing and inspection before leaving the factory, customers can be assured of receiving reliable, top-tier equipment.The company understands that purchasing industrial machinery is a significant investment for businesses, and as such, they offer comprehensive aftersales service and technical support. This ensures smooth implementation, operational efficiency, and minimal downtime for customers.Looking Towards the Future:As the manufacturing industry embraces automation and digitization, the introduction of the cheap CNC fiber laser system marks a significant step forward. With its affordable price tag, precise cutting capabilities, and user-friendly interface, this cutting-edge machine empowers businesses of all sizes to thrive and innovate in the highly competitive global market.In conclusion, the advent of the cheap CNC fiber laser system is set to revolutionize the manufacturing industry. By combining affordability, versatility, and efficiency, this groundbreaking technology represents a paradigm shift in the accessibility and utilization of laser cutting and engraving. With its commitment to quality and customer satisfaction, the company continues to drive progress and shape the future of manufacturing.

Affordable and Efficient CNC Fiber Laser Machines to Boost Your Business

Title: Cutting-Edge Cheap CNC Fiber Laser Factory Revolutionizes Manufacturing IndustryIntroduction:In a groundbreaking development, a renowned CNC fiber laser manufacturer has emerged as a pioneer in the field of affordable and cutting-edge laser machinery. This company, whose identity we cannot disclose due to brand name restrictions, has revolutionized the manufacturing industry with its cost-effective and efficient solutions. Combining advanced technology with unmatched precision, this cheap CNC fiber laser factory is setting new standards in the market. This news article delves into the company's background and highlights its contributions to the manufacturing sector.Company Background:Established several decades ago, this CNC fiber laser manufacturer has gained a solid reputation for producing high-quality and reliable laser machinery. Their commitment to innovation has allowed them to stay ahead in an ever-evolving industry. The company prides itself on its ability to design and manufacture laser cutting and engraving machines that are not only affordable but also deliver outstanding performance. They cater to a diverse range of industries, including automotive, aerospace, electronics, and signage.Key Features of the CNC Fiber Laser Factory:1. Advanced Technology:The cheap CNC fiber laser factory is equipped with state-of-the-art technology that ensures optimal performance and accuracy. The integration of fiber laser technology enhances the cutting and engraving capabilities, providing precise and intricate results. Advanced software enables seamless operation and compatibility with various design formats.2. Cost-Effective Solutions:Unlike many competitors, this manufacturer recognizes the importance of affordability. Their laser machinery offers cost-effective solutions without compromising on quality. By optimizing the manufacturing processes, they manage to reduce the overall costs while maintaining high precision and reliability. This ensures that even smaller businesses can benefit from the advantages of CNC fiber laser technology.3. Customizable Options:Understanding the diverse needs of their clientele, this cheap CNC fiber laser factory provides customizable options to suit specific requirements. Customers can choose from different power levels, bed sizes, and additional features based on their production demands. The company's flexibility in catering to individual needs sets them apart from their peers.4. Extensive Application Range:The laser machinery produced by this manufacturer finds extensive applications across various industries. Organizations can utilize these advanced tools for cutting and engraving different materials ranging from metals and plastics to wood and ceramics. The CNC fiber laser factory's versatility allows customers to expand their production capabilities and explore new business opportunities.5. Superior Customer Support:Aside from providing superior products, the company ensures excellent customer support throughout the buying process and beyond. Their dedicated team of experts offers comprehensive training, guidance, and prompt technical assistance, ensuring a smooth transition to utilizing CNC fiber laser machinery.Conclusion:This groundbreaking CNC fiber laser factory, which we are unable to publicly reveal due to brand name restrictions, is revolutionizing the manufacturing industry. By combining cutting-edge technology, cost-effective solutions, and extensive customization, this manufacturer stands out among its competitors. The affordability and precision of their laser machinery open up new possibilities for businesses of all sizes, allowing them to enhance productivity and explore uncharted territories. With the cheap CNC fiber laser factory's superior customer support and dedication to innovation, the future of manufacturing looks promising.

Affordable 4-Axis Hydraulic Press Brake for Your Industry Needs

As companies worldwide continue to search for ways to enhance their efficiency and optimize output, the use of high-tech machinery and equipment has become a must-have. This is true across various sectors, but particularly crucial within manufacturing. With the complexities involved in bending and shaping metal, the need for advanced press brake machines is more pressing than ever before.To meet this demand, one company has introduced a new, innovative 4-axis press brake machine, designed to simplify the metalworking process. This new machine combines advanced technology with cutting-edge engineering and is based on a sophisticated system that incorporates working speeds and accurate angular performance, making it one of the most efficient press brake machines on the market today. With a focus on automation, the company has designed this press brake with an electronically controlled 4-axis back gauge that can be programmed to automatically adjust each time a different component is being bent. This enables the operator to achieve precise positioning, with a high degree of repeatability, thereby reducing the need for manual intervention and increasing the overall speed and efficiency of the process. With this machine, manufacturers can lower their costs while maintaining a high level of accuracy.According to a representative from the company, the new press brake machine offers unparalleled precision, speed, and versatility. With its advanced technological features, this press brake machine is poised to revolutionize metalworking processes, reducing production times while also maintaining a high level of quality.One of the key advantages of this press brake machine is its ability to perform multiple operations with a single setup. This feature significantly reduces the need for manual intervention and speeds up the bending process. With several modes of operation, including standalone, automatic, and semi-automatic, this machine is highly adaptable and can be customized to suit the specific needs of any manufacturing operation.To further enhance its performance, this press brake machine is constructed from high-quality materials, ensuring that it can handle even the most demanding workloads. With an ergonomic design that reduces operator fatigue, this machine is easy to use and can be operated with minimal training. Furthermore, the machine is highly customizable, allowing manufacturers to choose from a range of options, including different hydraulic systems, press brake controllers, and more.The company spokesperson explained that the new press brake machine is highly reliable and offers a low cost of ownership. With its advanced features and durable construction, it requires minimal maintenance, reducing downtime and maximizing productivity. Whether you are a small startup or a large corporation, this press brake machine is designed to meet your specific needs, ensuring that you can get your products to market quickly and efficiently.According to industry experts, this advanced press brake machine is set to redefine the metalworking industry, making it easier and more cost-effective for manufacturers to produce high-quality products. With a focus on innovation and automation, this machine is poised to become one of the most important pieces of equipment in any manufacturing plant. By reducing manual intervention, increasing productivity, and maintaining precision accuracy, this cutting-edge press brake machine is set to be a game-changer in the industry.In conclusion, this new 4-axis press brake machine is a must-have for any modern manufacturing operation seeking to streamline processes while maintaining a high level of accuracy and precision. With its advanced capabilities, customizable options, and low cost of ownership, this machine is highly supportive of businesses in positively impacting bottom line results and competitive strengths. The innovative technology behind this press brake machine underscores the company's ongoing commitment to advancing metalworking processes and supporting the growth of businesses worldwide.

Top CNC Punch Machine Companies in 2021

CNC Punch Machine Companies (no brand name) are leading the way in the manufacturing industry with their cutting-edge technology and innovative solutions. These companies are revolutionizing the way products are made, providing efficient and high-quality production capabilities for a wide range of industries.With a commitment to excellence, CNC Punch Machine Companies (no brand name) have established themselves as industry leaders in the design and manufacture of precision punching machines. Their state-of-the-art facilities utilize the latest in CNC technology to produce machines that are at the forefront of efficiency and precision.The company's dedication to research and development has led to the creation of cutting-edge punching machines that are capable of handling a wide variety of materials, including steel, aluminum, and other metals. Their machines are designed to meet the diverse needs of their customers, providing solutions for complex and intricate punching tasks.One of the key factors that set CNC Punch Machine Companies (no brand name) apart from their competitors is their commitment to providing comprehensive customer support. They offer a range of services, including installation, training, and ongoing maintenance, to ensure that their customers are able to maximize the performance of their punching machines.In addition to their dedication to customer support, CNC Punch Machine Companies (no brand name) are also committed to sustainability and environmental responsibility. Their machines are designed to minimize waste and energy consumption, helping their customers to reduce their carbon footprint and operate more sustainably.Furthermore, CNC Punch Machine Companies (no brand name) are constantly pushing the boundaries of what is possible in the field of punching technology. Their research and development team is constantly exploring new innovations and breakthroughs, driving the industry forward and setting new standards for quality and performance.In order to maintain their position as industry leaders, CNC Punch Machine Companies (no brand name) are always looking for ways to improve and innovate. They invest heavily in research and development, continuously looking for new ways to enhance the performance and efficiency of their punching machines.With a focus on quality, efficiency, and innovation, CNC Punch Machine Companies (no brand name) are shaping the future of manufacturing. Their commitment to excellence and customer satisfaction has established them as trusted partners for industries that demand the highest standards of precision and performance.As CNC Punch Machine Companies (no brand name) continue to push the boundaries of what is possible in the field of punching technology, they are poised to lead the industry into a new era of manufacturing excellence. With their advanced technology and unwavering commitment to quality, they are helping their customers to achieve new levels of efficiency and precision in their production processes.

Complete Guide to Turret Punching Process in China

China Turret Punching Process Revolutionizes Sheet Metal FabricationThe sheet metal fabrication industry has experienced a significant technological advancement with the introduction of the China Turret Punching Process. This innovative method has transformed the way sheet metal components are manufactured, offering a wide range of benefits that have revolutionized the production process.The China Turret Punching Process, developed by an industry-leading manufacturer, {Company Name}, is a high-speed and cost-effective method for creating precision sheet metal parts. With its advanced CNC technology and automatic tool changing capabilities, this process is capable of producing complex 2D and 3D shapes with unparalleled accuracy and efficiency.{Company Name} is a renowned leader in the sheet metal fabrication industry, with a proven track record of delivering high-quality products to a diverse range of clients. With decades of experience and expertise, the company has continuously strived to innovate and improve its manufacturing processes to meet the evolving needs of its customers.The introduction of the China Turret Punching Process is a testament to {Company Name}'s commitment to excellence and innovation. By investing in cutting-edge technology and state-of-the-art machinery, the company has positioned itself as a forward-thinking industry leader capable of delivering superior products and services.One of the key advantages of the China Turret Punching Process is its ability to drastically reduce lead times and production costs. The high-speed punching and forming capabilities of the process enable rapid prototyping and mass production of sheet metal components, making it an ideal solution for both small and large-scale manufacturing operations.Furthermore, the CNC technology integrated into the process ensures exceptional accuracy and repeatability, allowing for the creation of intricate designs and tight tolerances. This level of precision is crucial for industries such as aerospace, automotive, electronics, and telecommunications, where quality and consistency are paramount.In addition to its speed and accuracy, the China Turret Punching Process offers versatility in terms of material compatibility. Whether working with stainless steel, aluminum, copper, or other types of sheet metal, the process is capable of handling a wide variety of materials to meet the diverse needs of different industries.{Company Name} has successfully utilized the China Turret Punching Process to enhance its production capabilities and deliver unmatched value to its customers. By streamlining the manufacturing process and optimizing efficiency, the company has been able to offer competitive pricing and fast turnaround times without compromising on quality.The impact of the China Turret Punching Process extends beyond the internal operations of {Company Name}. Its adoption has allowed the company to take on more complex projects and meet the growing demand for custom sheet metal components in various industries. This expansion has led to new opportunities for growth and increased market competitiveness.In conclusion, the China Turret Punching Process has set a new standard for sheet metal fabrication, offering a combination of speed, precision, and versatility that has transformed the industry. As {Company Name} continues to leverage this cutting-edge technology, it remains at the forefront of innovation, demonstrating its commitment to delivering excellence in sheet metal manufacturing. With the China Turret Punching Process, {Company Name} is well-positioned to meet the evolving needs of its customers and drive the future of sheet metal fabrication.