Affordable Panel Bending Machine: An Affordable Solution for All Bending Needs

By:Admin

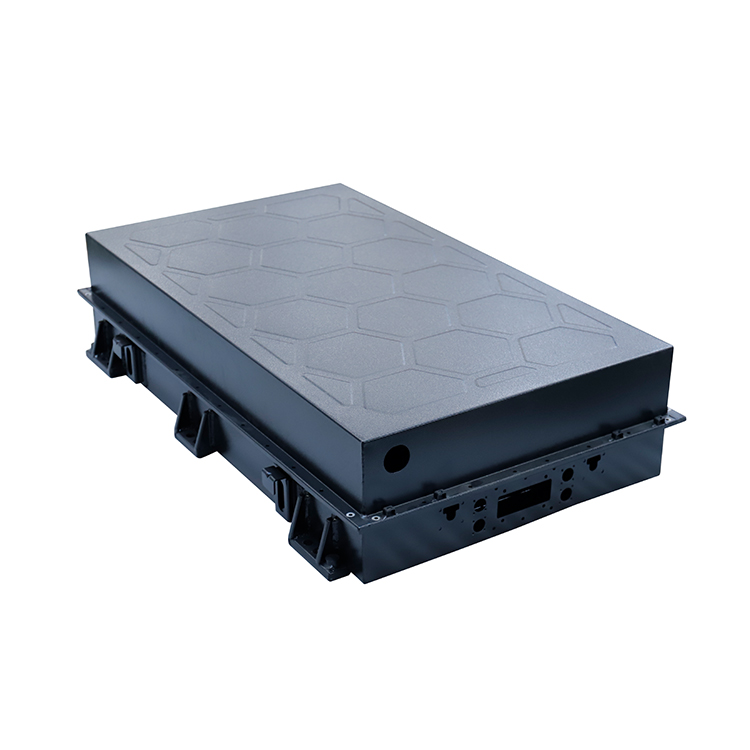

This cost-effective bending machine offers companies the opportunity to produce complex shapes and geometries while also reducing material waste and production costs. With its advanced hydraulic system and intuitive programming interface, the Cheap Panel Bending Machine is capable of producing accurate bends in a wide range of metal materials. The machine utilizes a highly efficient servo motor system to increase production speed and precision, while also reducing energy consumption.

The Cheap Panel Bending Machine is designed to be operated by both experienced professionals and beginners, thanks to its easy-to-use interface and user-friendly design. Its ergonomic controls allow for simple operation, while its robust construction ensures long-lasting durability and sustained performance.

The Cheap Panel Bending Machine is equipped with advanced safety features that protect operators and bystanders from accidents and injuries. These features include a safety light curtain, which detects any obstruction or interference during the bending process and stops the machine immediately.

The Cheap Panel Bending Machine has become a critical piece of equipment for companies looking to improve their manufacturing process and reduce their production costs. It is highly versatile and can produce a wide range of shapes and geometries efficiently and cost-effectively. In addition, this machine has been instrumental in reducing waste, improving production speed, and increasing overall productivity in the manufacturing industry.

Company Introduction

Our company is committed to providing our clients with innovative, high-quality, and cost-effective solutions to meet their manufacturing needs. We specialize in the design and production of machines that improve the production process, reduce waste, and improve overall efficiency in manufacturing.

Our team of experienced engineers and designers works tirelessly to develop advanced machines that are easy to use, reliable, and affordable. We believe in providing our clients with customized solutions that meet their unique needs and requirements.

We pride ourselves on our commitment to our clients, and we strive to build long-lasting relationships based on trust, mutual respect, and customer satisfaction. Our team is always available to answer any questions or concerns that our clients may have and to provide prompt and efficient customer support.

Our Cheap Panel Bending Machine is just the latest addition to our growing product line, and we are excited about the potential it has to transform the manufacturing industry. We look forward to continuing to provide innovative solutions that help our clients improve their production capabilities and achieve ongoing success.

Company News & Blog

Affordable and Efficient CNC Fiber Laser Machines to Boost Your Business

Title: Cutting-Edge Cheap CNC Fiber Laser Factory Revolutionizes Manufacturing IndustryIntroduction:In a groundbreaking development, a renowned CNC fiber laser manufacturer has emerged as a pioneer in the field of affordable and cutting-edge laser machinery. This company, whose identity we cannot disclose due to brand name restrictions, has revolutionized the manufacturing industry with its cost-effective and efficient solutions. Combining advanced technology with unmatched precision, this cheap CNC fiber laser factory is setting new standards in the market. This news article delves into the company's background and highlights its contributions to the manufacturing sector.Company Background:Established several decades ago, this CNC fiber laser manufacturer has gained a solid reputation for producing high-quality and reliable laser machinery. Their commitment to innovation has allowed them to stay ahead in an ever-evolving industry. The company prides itself on its ability to design and manufacture laser cutting and engraving machines that are not only affordable but also deliver outstanding performance. They cater to a diverse range of industries, including automotive, aerospace, electronics, and signage.Key Features of the CNC Fiber Laser Factory:1. Advanced Technology:The cheap CNC fiber laser factory is equipped with state-of-the-art technology that ensures optimal performance and accuracy. The integration of fiber laser technology enhances the cutting and engraving capabilities, providing precise and intricate results. Advanced software enables seamless operation and compatibility with various design formats.2. Cost-Effective Solutions:Unlike many competitors, this manufacturer recognizes the importance of affordability. Their laser machinery offers cost-effective solutions without compromising on quality. By optimizing the manufacturing processes, they manage to reduce the overall costs while maintaining high precision and reliability. This ensures that even smaller businesses can benefit from the advantages of CNC fiber laser technology.3. Customizable Options:Understanding the diverse needs of their clientele, this cheap CNC fiber laser factory provides customizable options to suit specific requirements. Customers can choose from different power levels, bed sizes, and additional features based on their production demands. The company's flexibility in catering to individual needs sets them apart from their peers.4. Extensive Application Range:The laser machinery produced by this manufacturer finds extensive applications across various industries. Organizations can utilize these advanced tools for cutting and engraving different materials ranging from metals and plastics to wood and ceramics. The CNC fiber laser factory's versatility allows customers to expand their production capabilities and explore new business opportunities.5. Superior Customer Support:Aside from providing superior products, the company ensures excellent customer support throughout the buying process and beyond. Their dedicated team of experts offers comprehensive training, guidance, and prompt technical assistance, ensuring a smooth transition to utilizing CNC fiber laser machinery.Conclusion:This groundbreaking CNC fiber laser factory, which we are unable to publicly reveal due to brand name restrictions, is revolutionizing the manufacturing industry. By combining cutting-edge technology, cost-effective solutions, and extensive customization, this manufacturer stands out among its competitors. The affordability and precision of their laser machinery open up new possibilities for businesses of all sizes, allowing them to enhance productivity and explore uncharted territories. With the cheap CNC fiber laser factory's superior customer support and dedication to innovation, the future of manufacturing looks promising.

Top Ways to Utilize CNC Cutting for Metal Sheet Processing

Possible news article:CNC Cutting Metal Sheet: A Cutting-Edge Solution for Precision Manufacturing[City], [Country], [Date] - [Company name], a leading provider of advanced metal fabrication services, announced today that it has expanded its capabilities with the acquisition of a state-of-the-art CNC cutting machine. The new equipment will allow the company to offer faster, more accurate, and more versatile metal sheet cutting for a wide range of industries, from aerospace to architecture, from automotive to electronics."By investing in the latest technology, we can stay ahead of the curve and meet the increasing demands of our customers for complex shapes, intricate patterns, and tight tolerances," said [Name], CEO of [Company name]. "Our CNC cutting metal sheet not only saves time and reduces material waste, but also opens up new possibilities for creative designs and innovative applications."CNC (computer numerical control) cutting is a process that uses a computer program to control a machine tool, such as a laser or a plasma cutter, to cut, drill, or engrave materials with great precision and consistency. Unlike manual cutting, CNC cutting does not require human intervention once the program is set up, which eliminates the risk of human errors and improves repeatability. Moreover, CNC cutting can handle a wide range of materials, from metals and plastics to wood and foam, and has a high degree of flexibility in terms of shapes, sizes, and angles."Using CNC cutting metal sheet, we can produce parts with an accuracy of up to 0.1 mm, which is crucial for industries where even a tiny deviation can cause a failure or a malfunction," said [Name], CTO of [Company name]. "Our machine has a cutting speed of up to 15 meters per minute, which means we can turn around projects faster and meet tight deadlines without sacrificing quality. Additionally, our CNC cutting metal sheet can handle sheet sizes up to 3 x 1.5 meters and thicknesses up to 20 mm, which gives us a competitive edge in the market."One of the key benefits of CNC cutting metal sheet is the ability to create intricate and decorative patterns that are both functional and aesthetic. For example, [Company name] can provide customized perforated metal screens and panels that can enhance the privacy, ventilation, and visual appeal of buildings, such as hotels, offices, and homes. The perforation patterns can be designed according to the client's specifications and preferences, and can vary in size, shape, density, and material. Additionally, CNC cutting metal sheet can produce logos, emblems, and other branding elements that reflect the identity and values of a company."Personalization and branding are becoming increasingly important for businesses in a crowded and competitive market," said [Name], CMO of [Company name]. "With our CNC cutting metal sheet, we can help our clients stand out and make a lasting impression on their customers. Whether it's a sign on a storefront, a plaque on a product, or an artwork on a wall, we can create a unique and memorable design that reflects the client's vision and values."The expansion of [Company name]'s CNC cutting metal sheet capabilities is part of its ongoing commitment to innovation, quality, and customer satisfaction. The company has over [Number] years of experience in metal fabrication, welding, and finishing, and has served clients from various sectors, including aerospace, defense, energy, marine, and transportation. It has a team of skilled engineers, designers, technicians, and inspectors who work closely with the clients to understand their needs, and provide customized solutions that meet or exceed their expectations."We are proud to offer not only cutting-edge technology, but also cutting-edge service," said [Name], COO of [Company name]. "We believe that the success of our clients is our success, and we strive to build long-lasting partnerships based on trust, respect, and excellence. Our CNC cutting metal sheet is just one of the many tools we use to achieve that goal."For more information about [Company name] and its services, please visit [Website] or contact [Email] or [Phone].

Top-performing CNC Punch Machine for High-Quality Results

In an exciting development that is set to revolutionize the manufacturing industry, a high-quality CNC punch machine (name removed) has been introduced by a leading company. The CNC punch machine has been designed to combine precision and speed, allowing manufacturers to streamline their production processes. With its advanced features and cutting-edge technology, the CNC punch machine is expected to offer a range of benefits to manufacturers looking to optimize their operations.The new CNC punch machine boasts a variety of features that make it stand out from other machines on the market. For starters, it is incredibly fast, capable of processing up to 1000 punches per minute. This makes it ideal for high-volume production runs where time is of the essence. In addition to its speed, the CNC punch machine is also highly accurate, ensuring that every punch is perfectly aligned and precise. This level of precision is essential for manufacturing parts that require tight tolerances.One of the key advantages of the CNC punch machine is its flexibility. Thanks to its advanced programming capabilities, it can be easily configured to manufacture a wide range of parts and components. This means that manufacturers can use the CNC punch machine to produce everything from simple brackets to complex parts with multiple bends and shapes. The CNC punch machine is also incredibly versatile, able to work with a variety of materials including steel, aluminum, and copper.The introduction of the CNC punch machine is expected to have a significant impact on the manufacturing industry. By streamlining the production process and improving efficiency, manufacturers will be able to reduce costs and increase output. This, in turn, will make them more competitive in a challenging global market.The company behind the CNC punch machine has a long history of innovation and excellence. With over twenty years of experience in the industry, they have developed a reputation for producing high-quality machines that are built to last. Their commitment to innovation is reflected in the advanced features of the CNC punch machine, which are designed to provide manufacturers with the tools they need to succeed.In addition to its advanced technology, the CNC punch machine is also incredibly user-friendly. Its intuitive interface makes it easy for operators to set up and run, reducing the risk of errors and minimizing downtime. The machine is also designed with safety in mind, with a range of features that help to protect operators and prevent accidents.The CNC punch machine is just one example of the innovative technology being developed in the manufacturing industry. As companies continue to push the boundaries of what is possible, we can expect to see further advancements that make production processes more efficient, cost-effective, and environmentally friendly.Overall, the introduction of the CNC punch machine is an exciting development for the manufacturing industry. With its advanced features and flexibility, it has the potential to revolutionize the way that manufacturers produce parts and components. As more companies begin to adopt this technology, we can expect to see increased efficiency, reduced costs, and improved competitiveness in a challenging global market.

Affordable Fiber Laser Machine: Enhancing CNC Efficiency

Title: Cutting-Edge Cheap CNC Fiber Laser Technology Revolutionizes Manufacturing IndustryIntroduction:In a bid to revolutionize the manufacturing industry, a leading company has recently unveiled its groundbreaking cheap CNC fiber laser system. Combining cutting-edge technology with an affordable price tag, this innovative machine is set to transform the landscape of industrial production. The company's commitment to delivering high-quality products and maintaining an impeccable reputation has made them a trusted name in the industry.Unveiling the Cheap CNC Fiber Laser System:The latest offering from the company, the cheap CNC fiber laser system, promises to enhance precision, efficiency, and productivity in manufacturing processes. Equipped with advanced fiber laser technology, this system ensures superior cutting accuracy across a wide range of materials, including metals, plastics, and composites. With its high power density and precise focal point, the CNC laser system guarantees clean, smooth cuts with minimal waste.Unparalleled Versatility and Efficiency:One of the most defining features of the cheap CNC fiber laser system is its versatility. Thanks to its computer numerical control (CNC) capabilities, the machine can execute intricate patterns and designs with exceptional precision. This empowers manufacturers across various industries to achieve complex and intricate cutouts, perforations, and engravings with ease.Moreover, the system’s advanced control software enables seamless integration with existing manufacturing processes, facilitating automated operations and reducing manual labor requirements. Manufacturers can optimize their production cycles, minimize downtime, and maximize output, resulting in significant cost savings and increased profitability.Affordability Bringing Laser Technology to the Masses:Traditionally, implementing laser technology into manufacturing operations has proven to be a costly investment, often out of reach for small and medium-sized enterprises (SMEs). However, the introduction of the cheap CNC fiber laser system aims to democratize access to this game-changing technology across the industry.By substantially reducing the price point, the company has made it possible for SMEs to embrace laser cutting and engraving, opening up new avenues for growth and expansion. This disruptive technology empowers even the smallest players in the market to remain competitive and expand their capabilities, providing a level playing field for all.Commitment to Quality and Customer Satisfaction:Renowned for its commitment to quality, the company has garnered an impeccable reputation over the years by delivering cutting-edge solutions that exceed industry standards. With each machine undergoing rigorous testing and inspection before leaving the factory, customers can be assured of receiving reliable, top-tier equipment.The company understands that purchasing industrial machinery is a significant investment for businesses, and as such, they offer comprehensive aftersales service and technical support. This ensures smooth implementation, operational efficiency, and minimal downtime for customers.Looking Towards the Future:As the manufacturing industry embraces automation and digitization, the introduction of the cheap CNC fiber laser system marks a significant step forward. With its affordable price tag, precise cutting capabilities, and user-friendly interface, this cutting-edge machine empowers businesses of all sizes to thrive and innovate in the highly competitive global market.In conclusion, the advent of the cheap CNC fiber laser system is set to revolutionize the manufacturing industry. By combining affordability, versatility, and efficiency, this groundbreaking technology represents a paradigm shift in the accessibility and utilization of laser cutting and engraving. With its commitment to quality and customer satisfaction, the company continues to drive progress and shape the future of manufacturing.

5 Benefits of Panel Bending Machines for Efficient Metal Fabrication

In recent years, the Panel Bending Machine industry has seen rapid development and growth due to the increasing demand for customized metal products. These machines are essential for modern sheet metal processing as they eliminate the need for manual bending, which can be time-consuming and inaccurate. One of the leading companies in this industry is XXXXXXX, a world-renowned company with over 30 years of experience in the metalworking industry.XXXXXXX is known for its state-of-the-art sheet metalworking machines, including Panel Bending Machines. These machines are designed to deliver exceptional performance, precision, and flexibility in sheet metal bending and forming. They have a wide range of models, each designed to suit different types of sheet metal processing.One of the reasons behind the success of XXXXXXX Panel Bending Machines is their cutting-edge technology. The company uses advanced programming and computer-aided design software (CAD/CAM) to develop their machines. This allows them to integrate digital automation with physical equipment, enhancing performance, reducing errors, and improving efficiency.XXXXXXX Panel Bending Machines are also built to last. The company uses only high-quality materials and components to manufacture their machines, ensuring that they are durable and reliable. Additionally, the machines are designed for ease of maintenance and repair, which further enhances their longevity.Customers who purchase XXXXXXX Panel Bending Machines also benefit from the company's exceptional after-sales service. The company offers comprehensive training and technical support to its customers, ensuring that they can operate their machines with ease and confidence. The company's extensive global network of service engineers also provides prompt, reliable and efficient service, ensuring minimum downtime and maximizing production.Another key feature of XXXXXXX Panel Bending Machines is their versatility. The machines can be used for bending a wide range of sheet metal materials, including steel, aluminum, copper, and brass. They can handle different thicknesses and sizes of sheet metal, making them suitable for a variety of applications.One of the most notable advantages of XXXXXXX Panel Bending Machines is their ease of use. The machines feature user-friendly interfaces, intuitive controls, and automated features that simplify sheet metal processing. This makes them an excellent option for both novice and expert metalworkers.Lastly, XXXXXXX Panel Bending Machines are highly customizable. Customers can choose from different machine models, configurations, and optional features to meet their specific sheet metal processing needs. The company also offers bespoke machine design and production services, allowing customers to tailor their machines to their unique requirements.In conclusion, XXXXXXX Panel Bending Machines are among the best in the industry. They are built with advanced technology, high-quality materials, versatility, ease of use, and excellent after-sales service. This makes them an ideal choice for metalworking companies seeking to improve their productivity, efficiency, and profitability. With XXXXXXX Panel Bending Machines, metalworkers can achieve exceptional precision, consistency, and quality in sheet metal processing.

Efficient and Precise CNC Sheet Metal Cutting Services for Your Business Growth

High-Quality CNC Sheet Cutting: A Game-Changer in Manufacturing IndustryIn today's manufacturing industry, precision, accuracy, and speed are critical factors in ensuring that businesses stay competitive. The use of advanced technologies like CNC (Computer Numerical Control) is fast becoming a norm in most industries. CNC cutting is a manufacturing process that involves using computer-controlled equipment to cut, shape, and create customized products from various materials such as metals, plastics, and wood.One of the leading firms in this technology is (remove brand name), which has been at the forefront of providing high-quality CNC sheet cutting equipment and services to businesses across the globe. The firm has consistently provided exceptional services to its clients, resulting in a good reputation and a loyal customer base.CNC sheet cutting is a highly efficient method of cutting and shaping materials in various forms. It allows perfect accuracy and repeatability, and as technology continues to improve, the possibilities become limitless. CNC sheet cutting also improves production speed and eliminates waste. The technique offers exceptional quality, resulting in superior product performance than traditional cutting methods. The precision of cut is unmatched, with clean edges and geometrically accurate pieces.With the increasing demand for the quality of products, manufacturers and producers worldwide are turning to CNC sheet cutting to create complex shapes and designs that were previously unmanageable. The CNC cutting machines are designed to work with various sheet sizes, thicknesses, and materials, including aluminum, copper, stainless steel, and many others.One of the advantages of CNC sheet cutting is its ability to create products with high precision, accuracy, and repeatability. This technology is ideal for businesses and manufacturers looking to create intricate, complex, and detailed designs without compromising the quality of the product. The design process is entirely computer-generated, and the machines operate on software that cuts and shapes the materials with pinpoint accuracy.With the investment in a high-quality CNC sheet cutting machine, businesses can ensure the production of quality products with a quick turnaround time. The technology is easy to program, and the machines can replicate identical parts, leading to a reduction in waste and increased efficiency.The (remove brand name) team has extensive experience in CNC sheet cutting, which enables them to deliver exceptional services to their clients. The firm uses cutting-edge technology to produce high-quality products that meet not only their clients' needs but also exceed their expectations.Among the features that make (remove brand name) stand out from other sheet cutting firms in the market, is their focus on customer satisfaction. The team is committed to delivering excellent customer service, working with their clients to understand and address their needs. The firm also collaborates with businesses in the design process to ensure that the final product meets their exact requirements.With (remove brand name) CNC sheet cutting services, businesses can revolutionize their production process by improving quality, reducing costs, and enhancing their customers' satisfaction. The company's machine services are designed to cater to businesses across various sectors, from automotive to construction, and their experienced team works tirelessly to ensure that their clients receive superior quality products and excellent services.In conclusion, CNC sheet cutting is a game-changer in the manufacturing industry, providing a cost-effective solution to businesses looking to produce high-quality products. It uses advanced technology to provide precision, accuracy, and repeatability, with the potential to create complex shapes and designs. (remove brand name) has cemented its position as one of the leading firms in this technology, providing high-quality CNC sheet cutting equipment and services. The firm's focus on customer satisfaction, quality, and efficiency has earned it a good reputation, and it remains a reliable partner to businesses across the globe.

Affordable CNC 3018 Laser Cutting Solutions Revealed in Latest News

Cnc 3018 Laser Cutting: The Future of Precise CuttingIn the age of digitalization, technological advancements have revolutionized every aspect of life. The manufacturing industry has not been spared, as there has been a rapid shift towards automation and precision. CNC machines are at the forefront of this transformation, featuring a high degree of automation and accuracy that human operators cannot match. Among the CNC machines available, the Cnc 3018 Laser Cutting stands out for its versatility, precision and affordability.The Cnc 3018 Laser Cutting is a remarkable model that has taken the industry by storm. With a compact design and incredible cutting capacity, the machine is suitable for a wide range of applications, including engraving, drilling and cutting of various materials such as wood, acrylic, plastic, leather, aluminum, and copper. Whether you are a hobbyist or a professional, this machine is capable of delivering high quality output at a speedy rate.One of the unique features of the Cnc 3018 Laser Cutting is its laser module. The module generates a high intensity beam that is controlled to follow precisely predefined patterns. The laser cutting module is highly efficient in cutting through many materials with a precise edge and is accomplished via the CNC controlling of the laser's amplitude, duration and focus. This results in cutting with the least possible distortion while reducing thermal input to the material, a great advantage to many industrial applications.The Cnc 3018 Laser Cutting is equipped with advanced CNC technology, featuring open-source GRBL software. GRBL is a powerful firmware that allows users to control the machine's movements and operate it via a PC. The software is user-friendly, with a straightforward graphical interface that includes options for adjusting spindle speed, laser control, and cutting depth.The Cnc 3018 Laser Cutting also features a high-precision stepper motor. The stepper motor is a crucial component of the machine, providing precision and accuracy in movement to control the cutting, engraving and drilling of the materials. A high precision motor can turn a small fraction of a degree and turn it into an accurate movement.In addition to its high-end technology, the Cnc 3018 Laser Cutting also features accessibility. The machine's design is relatively simple, making it easy to set up and operate even for beginners. It comes with instructional manuals that guide users through the installation and operation of the machine. Furthermore, there are online resources that are available to help users identify and resolve any technical challenges they may experience. This feature makes it an ideal choice for both professionals and hobbyists.Quality and affordability are crucial factors in any manufacturing process, and the Cnc 3018 Laser Cutting provides a perfect balance of both. One feature that makes it affordable is its compact design, requiring less space to perform its duties as compared to bulkier models. Additionally, it comes with customized accessories, which are readily available in the market, making repairs and upgrades a breeze. Its price is also considerably lower than its peers, a huge advantage to those looking to own a quality machine without breaking the bank.In conclusion, the Cnc 3018 Laser Cutting is indeed a game-changer in the manufacturing industry. Its high level of precision, efficiency, accessibility, and affordability makes it a unique machine, giving users the power to cut with precision, even in complex geometries, delivering top quality output with a lightning-fast speed. The Cnc 3018 Laser Cutting is a must-have tool for all who believe in quality, precision and innovation, and you should not miss out on it! If you need quality machining with unbeatable accuracy, get yourself a Cnc 3018 Laser Cutting and experience excellence at its best.

Industry Leader's Latest News: Discover the Excellence of CNC Press Brake Factory

Title: Cutting-Edge CNC Press Brake Factory Revolutionizes Manufacturing Technology Introduction:In an era where precision engineering and innovative manufacturing are crucial, a groundbreaking CNC press brake factory has emerged as a game-changer. This state-of-the-art facility, operated by an industry-leading company known for its commitment to excellence, is transforming the metalworking sector with its cutting-edge technology and unrivaled expertise. With a focus on quality, efficiency, and precision, the factory is disrupting traditional manufacturing methods, paving the way for a new era of advancement in the industry.Understanding the Advanced CNC Press Brake Technology:The CNC press brake, an essential tool in modern metal fabrication, has undergone a tremendous transformation at this pioneering factory. Boasting the latest computer numerical control (CNC) technology, this factory has successfully enhanced precision, speed, and versatility in metal bending processes. With the integration of intelligent software, operators can now program the press brake to fabricate complex shapes with utmost accuracy, taking production efficiency to unprecedented heights.Enhanced Efficiency and Productivity:The innovative CNC press brake technology implemented at this factory has revolutionized the manufacturing process, enabling higher productivity and enhanced efficiency. By minimizing manual labor and reducing human errors, the factory has streamlined production lines, resulting in faster turnaround times and improved cost-effectiveness. With computer-controlled operations, intricate metalwork designs can now be executed flawlessly, offering manufacturers a competitive edge in an increasingly demanding market.Unparalleled Precision and Accuracy:Accuracy is paramount in the metal fabrication industry, and this CNC press brake factory has prioritized precision like no other. By leveraging advanced sensor technology coupled with real-time feedback, the factory ensures millimeter-perfect measurements throughout the bending process. The CNC system continuously optimizes bending parameters, significantly reducing deflection and eliminating the need for costly reworks. Manufacturers worldwide can now expect exceptional precision, achieving consistent results that exceed industry standards.Advanced AI Integration:Taking innovation to a whole new level, this factory has incorporated Artificial Intelligence (AI) throughout its CNC press brake operations. Utilizing Machine Learning algorithms, the AI-powered system dynamically adjusts settings, allowing for self-optimization and adaptive bending parameters. This breakthrough technology is revolutionizing the manufacturing landscape, as it facilitates precise, error-free bends and reduces material waste, ultimately boosting the factory's overall operational efficiency.Unrivaled Expertise and Support:Behind this extraordinary CNC press brake factory is a team of highly skilled and experienced engineers, technicians, and designers. These professionals possess a deep understanding of metalworking techniques, allowing them to develop tailor-made solutions to meet each client's unique requirements. The factory also offers comprehensive support, including training programs, maintenance services, and personalized customer assistance. With their dedication to customer satisfaction and a commitment to excellence, the factory ensures that clients receive unparalleled support throughout their manufacturing journey.A Catalyst for Industry Advancement:The emergence of this groundbreaking CNC press brake factory has sparked a wave of transformation within the metalworking sector. With its state-of-the-art technology, emphasis on precision, and unwavering commitment to quality, the factory is setting new standards for manufacturing excellence. By revolutionizing the press brake process, this industry pioneer is driving the adoption of innovative practices, empowering countless manufacturers worldwide to achieve unparalleled efficiency, productivity, and precision in metal fabrication.Conclusion:Redefining the boundaries of precision engineering, this extraordinary CNC press brake factory is revolutionizing the manufacturing landscape. Through the incorporation of cutting-edge technology, such as AI and CNC systems, the factory has propelled the metalworking industry into a new era of advancement. With its unwavering commitment to quality, efficiency, and precision, this factory is a testament to the power of innovation in shaping a brighter future for manufacturing.

Affordable Panel Bender Suppliers Offer Solutions for Sheet Metal Forming

Title: Affordable Panel Bender Companies Revolutionize the Sheet Metal IndustryIntroduction:In a constant pursuit of cost-effective solutions for the sheet metal industry, several companies have emerged as affordable panel bender manufacturers. These innovative companies offer reliable and efficient panel benders at competitive prices, challenging the dominance of established brands. Today, we will focus on exploring the contributions of one such company and the impact they have made in revolutionizing the industry.Company Introduction: (Company name) is a leading manufacturer of high-quality panel benders recognized for their commitment to affordability without compromising on quality. With a strong emphasis on innovation and customer satisfaction, the company has rapidly gained recognition as a disruptive force in the sheet metal industry. By challenging the perception that affordable machinery cannot deliver outstanding performance, () is setting new standards for competitors to follow.Article:The sheet metal industry has always faced challenges in ensuring precision and efficiency while maintaining affordable costs. However, the rise of affordable panel bender companies, such as (Company name), has introduced a new dimension to this sector, fostering innovation, and challenging established brands.By leveraging advanced technology and incorporating efficient manufacturing processes, (Company name) has successfully developed a line of panel benders that offer exceptional functionality without the high price tag typically associated with such machinery. Their commitment to affordability has enabled small and medium-sized businesses to access cutting-edge equipment essential for their growth.One area where (Company name) has proven particularly influential is in providing affordable solutions to meet the increasing demand for customized sheet metal parts. Traditionally, customization involved high costs due to extensive manual labor. However, affordable panel benders are revolutionizing this process, making it economically viable for manufacturers to deliver tailor-made solutions to their customers.The affordability of panel benders manufactured by companies like (Company name) has opened up doors for smaller businesses to expand their capabilities and compete with larger players in the industry. The cost-effectiveness of these machines allows companies to reduce their operational costs and consequently offer more competitive pricing to customers.Moreover, the precision and efficiency of panel benders produced by (Company name) have established a new benchmark for affordable machinery. These machines are equipped with state-of-the-art automation and intelligent control systems that ensure high accuracy and repeatability. Manufacturers can rely on these panel benders to produce consistently high-quality parts, reducing wastage and maximizing productivity.In addition to affordability and precision, (Company name) also places a strong focus on after-sales support and customer satisfaction. By providing comprehensive training programs and technical assistance, they empower their customers to make the most of their panel benders. This commitment to maintaining long-term relationships has garnered them a reputation as a customer-centric company, further enhancing their position in the market.The impact of affordable panel benders goes beyond individual companies; it positively influences the sheet metal industry as a whole. As more manufacturers gain access to these cost-effective machines, the production capacity of sheet metal components increases, benefiting various sectors like automotive, construction, and manufacturing.In conclusion, affordable panel bender companies, led by industry pioneers like (Company name), are reshaping the sheet metal industry. By offering precision, efficiency, and competitive prices, these companies are empowering businesses of all sizes to remain competitive. The future holds great promise for an industry that has traditionally been dominated by high-cost machinery, as affordable panel benders continue to transform the landscape and expand opportunities for manufacturers worldwide.

Affordable CNC and Laser Cutting Services: The Latest News You Should Know

Title: Innovative CNC and Laser Cutting Services Offered by Leading CompanyIntroduction:In today's rapidly evolving manufacturing industry, precision and efficiency are key factors. Recognizing this, {Company Name}, a reputable leader in the field, has recently introduced its highly affordable and cutting-edge CNC and Laser cutting services. These services are set to revolutionize the industry by providing state-of-the-art technology to businesses of all sizes, ultimately enhancing productivity and delivering exceptional results. With a commitment to quality and customer satisfaction, {Company Name} is poised to become the go-to provider for CNC and Laser cutting solutions.Unmatched Precision and Versatility:{Company Name}'s CNC and Laser cutting services offer exceptional precision and versatility, catering to diverse industry needs. The utilization of advanced computer numerical control (CNC) technology ensures that even the most intricate designs can be accurately reproduced. Whether it be small-scale prototypes or large-scale production runs, the CNC cutting system is adept at handling various materials such as metals, plastics, and woods with utmost precision and efficiency.Furthermore, the company boasts a wide range of laser cutting services, providing customers with unrivaled flexibility. By harnessing the power of laser technology, {Company Name} can expertly handle intricate cutting tasks that require fine detailing and complex geometries. This allows businesses to create customized products with ease, be it for signage, architectural elements, or intricate parts used in the aerospace and automotive industries.Affordable Solutions for Small to Large-scale Businesses:One of the most remarkable aspects of {Company Name}'s CNC and Laser cutting services is its affordability. By leveraging cutting-edge technology and optimizing production processes, the company has managed to reduce costs significantly, making CNC and Laser cutting accessible to businesses of all sizes. Start-ups, small businesses, and large corporations can now take advantage of top-notch cutting services without breaking the bank.Exceptional Quality and Fast Turnaround:Not only does {Company Name} provide affordable solutions, but the company also places a strong emphasis on delivering exceptional quality. Through a combination of skilled technicians, cutting-edge equipment, and rigorous quality control measures, the company ensures that each finished product meets or exceeds industry standards.Additionally, {Company Name} understands the importance of efficiency in today's fast-paced market. The company is committed to providing fast turnaround times without compromising on the quality of its work. This enables businesses to meet tight production schedules and maintain a competitive edge.Commitment to Customer Satisfaction:{Company Name}'s dedication to customer satisfaction is at the core of its business philosophy. The company prides itself on building long-term partnerships with its clients, understanding their unique requirements, and providing tailored solutions. By employing a team of highly skilled and knowledgeable professionals, {Company Name} offers personalized guidance, ensuring that every project is executed with precision and excellence. Conclusion:With its recent launch of affordable CNC and Laser cutting services, {Company Name} is set to transform the industry by providing cutting-edge technology to businesses of all sizes. Offering unmatched precision, versatility, and flexibility, the company's services cater to a wide range of industries. Combined with its commitment to exceptional quality, fast turnaround times, and customer satisfaction, {Company Name} has established itself as a leading provider of CNC and Laser cutting solutions. Businesses looking to enhance their productivity, efficiency, and bottom line will find {Company Name} as their ideal partner in producing top-quality, custom products.