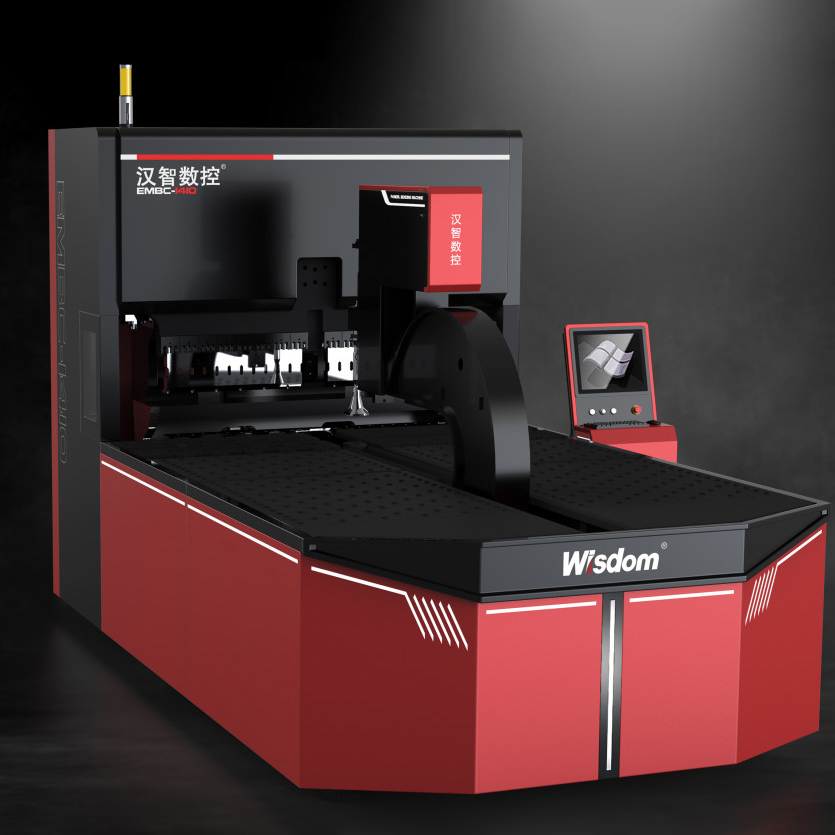

New Auto Bender Machine Launches in China, Promising Efficient Production

By:Admin

China Auto Bender Machine, a leading manufacturer in the sheet metal processing industry, has recently introduced its latest innovation in the form of a state-of-the-art auto bender machine. This cutting-edge technology is designed to revolutionize the way sheet metal is processed, offering enhanced precision, speed, and efficiency.

The new auto bender machine is equipped with advanced features that set it apart from traditional bending machines. Its high-speed servo motors and precision ball screw drive system allow for quick and accurate bending of sheet metal, significantly reducing production time and costs. In addition, the machine's user-friendly interface and intelligent programming enable operators to easily set up and control the bending process, resulting in improved productivity and quality output.

With a focus on innovation and continuous improvement, China Auto Bender Machine has been at the forefront of the sheet metal processing industry for many years. The company has a strong commitment to research and development, constantly pushing the boundaries of what is possible in the field of sheet metal bending technology. As a result, its products are known for their reliability, performance, and durability, making them a top choice for manufacturers and fabricators worldwide.

In addition to its cutting-edge technology, China Auto Bender Machine also boasts a team of skilled engineers and technicians who are dedicated to providing exceptional customer service and support. Whether it's assisting with machine installation, training operators, or troubleshooting technical issues, the company's knowledgeable staff is always ready to go the extra mile to ensure customer satisfaction.

Furthermore, China Auto Bender Machine is deeply committed to environmental sustainability and energy efficiency. The new auto bender machine is designed to minimize energy consumption and reduce waste, contributing to a greener and more sustainable manufacturing process. By prioritizing environmental responsibility, the company aims to not only benefit its customers but also make a positive impact on the planet.

As a global leader in the sheet metal processing industry, China Auto Bender Machine has established a strong presence in the international market, with a wide network of distributors and partners around the world. The company's reputation for excellence and innovation has earned it the trust and loyalty of numerous customers, who rely on its products to meet their sheet metal processing needs.

With the introduction of its latest auto bender machine, China Auto Bender Machine is once again demonstrating its commitment to pushing the boundaries of technology and delivering cutting-edge solutions to the sheet metal processing industry. As the demand for precision, speed, and efficiency continues to grow, the company remains dedicated to providing state-of-the-art equipment that meets and exceeds the expectations of its customers.

In conclusion, China Auto Bender Machine's new auto bender machine represents a significant advancement in sheet metal processing technology. With its advanced features, user-friendly interface, and environmental sustainability, it is poised to set a new standard for efficiency and performance in the industry. As the company continues to innovate and expand its global presence, it is undoubtedly a force to be reckoned with in the world of sheet metal bending technology.

Company News & Blog

Revolutionary New Machine Used in Panel Bending Process

In today's world, technology is advancing at an unprecedented pace, and it is crucial for businesses to keep up with the latest trends to remain competitive in the market. One such technology that has been aiding numerous businesses worldwide is the panel benders. While traditional metal forming technologies like punching and laser cutting have been in the industry for decades, panel bending has emerged as a crucial method for shaping metal sheets with high precision.One of the leading companies in the field of panel bending technology is (company name). They have been providing panel bending solutions for over thirty years, enabling businesses to boost their productivity by automating their metal forming processes. The company's advanced panel benders are designed to handle a wide variety of metals, including steel, aluminum, copper, and brass, with thickness ranging from 0.5 mm to 20 mm.With over 10,000 installations across the globe, (company name) have established themselves as a reliable partner for numerous businesses. Their panel benders are used in various industries, including automotive, aerospace, electronics, construction, and furniture. Some of the world's leading companies like Bosch, BMW, and Airbus have trusted their panel bending needs to (company name).One of the significant advantages of panel bending technology is its ability to produce intricate shapes at a high speed. Employing panel benders reduce the lead time, thus enabling businesses to meet tight deadlines while assuring high-quality production. The equipment's high flexibility also allows companies to produce small to large batches of products with minimal setup time and maximum precision, making it ideal for businesses that require quick and cost-effective production.Partnering with (company name) can help businesses to streamline their production processes and achieve greater efficiency. The company provides comprehensive support to their clients with a global network of experienced service engineers, ensuring that their equipment is well-maintained to deliver optimal performance. They also offer ongoing software updates to keep their clients' equipment up to date with the latest features.In conclusion, panel benders are a game-changer for businesses that seek efficient and cost-effective metal forming processes. (company name) panel benders provide businesses with the flexibility, precision, and speed required to stay ahead in the market. Their thirty-year experience enables them to offer high-quality solutions and unparalleled customer service, making them a trusted partner in the industry.

Affordable Panel Bending Equipment for Efficient Production

Cheap Panel Bending Equipment Revolutionizes Manufacturing IndustryPanel bending equipment has long been a crucial tool in the manufacturing industry, allowing for the precise bending of metal sheets to create a wide range of products. However, the high cost of such equipment has often been a barrier for small and medium-sized businesses looking to break into the market. That is, until now.The introduction of the affordable panel bending equipment from {Company Name} has been a game-changer for manufacturers of all sizes. This revolutionary new technology has made it possible for businesses to gain access to high-quality panel bending capabilities at a fraction of the cost of traditional machines.{Company Name} has been a leader in the manufacturing equipment industry for over two decades, known for its innovative and reliable products. The company has a strong reputation for providing high-quality machinery at competitive prices, making it a trusted name in the industry.With the release of their new affordable panel bending equipment, {Company Name} is once again proving their commitment to helping businesses thrive. This new offering is a testament to the company's dedication to providing practical solutions for the everyday challenges faced by manufacturers.The cheap panel bending equipment from {Company Name} is designed to be easy to use, making it accessible to even the most novice operators. Its intuitive design and user-friendly interface allow for quick setup and operation, saving businesses valuable time and resources.In addition to its affordability and ease of use, the equipment also boasts impressive capabilities. Its high-precision bending ensures consistent and accurate results, meeting the stringent quality standards required by today's manufacturing industry. This means that businesses can now produce high-quality products without breaking the bank.Furthermore, the equipment is built to be durable and reliable, minimizing downtime and maintenance costs. Its robust construction and long-lasting components make it a sound investment for businesses looking to boost their production capabilities without compromising on quality.The release of this cheap panel bending equipment has already made a significant impact on the manufacturing industry. Businesses that were previously unable to afford such machinery are now able to compete with larger companies, leveling the playing field and opening up new opportunities for growth and success."We are thrilled to introduce our affordable panel bending equipment to the market," said {Company Name}'s CEO. "We understand the challenges that businesses face when it comes to investing in new machinery, and we are proud to offer a solution that is both high-quality and budget-friendly. Our goal is to help businesses thrive, and this new equipment is a step towards achieving that."The response to the new offering has been overwhelmingly positive, with businesses praising the equipment for its reliability, affordability, and performance. Many have reported significant improvements in their production capabilities since implementing the new machinery, leading to increased efficiency and profitability.As the manufacturing industry continues to evolve, the demand for affordable and reliable equipment will only continue to grow. With the introduction of {Company Name}'s cheap panel bending equipment, businesses now have access to a solution that meets their needs without compromising on quality.In conclusion, the release of the affordable panel bending equipment from {Company Name} has brought about a significant shift in the manufacturing industry. By making high-quality machinery more accessible to businesses of all sizes, {Company Name} is helping to drive innovation and growth within the industry. As more businesses embrace this new technology, the potential for success and advancement in the manufacturing sector is boundless.

Highly Efficient CNC Punch Press Machine for Precision Metal Fabrication

[Company Name] Introduces Next-Generation CNC Punch Press Machine for Precision Metal Fabrication[City, State] - [Company Name], a leading manufacturer of innovative metal fabrication equipment, is proud to announce the release of its latest CNC punch press machine. This state-of-the-art machine is designed to revolutionize the metal fabrication industry with its advanced features and precision performance.The new CNC punch press machine is equipped with cutting-edge technology that allows for high-speed and high-precision fabrication of various metal materials. With its user-friendly interface and advanced control system, the machine offers unmatched accuracy and efficiency in punching, forming, and cutting metal parts."We are excited to introduce our new CNC punch press machine to the market," said [Spokesperson Name], the CEO of [Company Name]. "This machine represents the culmination of years of research and development, and we believe it will set a new standard for precision metal fabrication."The CNC punch press machine is designed to meet the demands of a wide range of industries, including automotive, aerospace, and electronics. Its versatile capabilities allow for the production of complex parts with tight tolerances, making it an invaluable tool for manufacturers seeking to enhance their production processes.One of the key features of the new CNC punch press machine is its ability to automatically change tools, significantly reducing downtime and increasing productivity. This feature, combined with the machine's high-speed punching and forming capabilities, allows for rapid and cost-effective production of metal parts.In addition to its cutting-edge technology, the CNC punch press machine is also designed with a focus on operator safety and ease of maintenance. The machine is equipped with advanced safety features to protect operators during operation, as well as an intuitive maintenance system to ensure optimal performance and longevity."Ensuring the safety of our operators and the reliability of our machines is a top priority for us," said [Spokesperson Name]. "We have incorporated the latest safety innovations and maintenance systems into our CNC punch press machine to provide our customers with peace of mind and a reliable solution for their metal fabrication needs."As part of its commitment to customer satisfaction, [Company Name] offers comprehensive training and support services for its CNC punch press machine. The company's team of experienced technicians is available to provide installation, training, and ongoing technical support to ensure that customers can maximize the potential of the machine."We understand that investing in a new piece of equipment is a significant decision for our customers," said [Spokesperson Name]. "That's why we are dedicated to providing unparalleled support and training to help our customers integrate the CNC punch press machine seamlessly into their operations."With the introduction of its new CNC punch press machine, [Company Name] is poised to further solidify its position as a leader in the metal fabrication industry. The company's commitment to innovation, quality, and customer satisfaction shines through in this latest addition to its product lineup.For more information about [Company Name] and its new CNC punch press machine, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of metal fabrication equipment, specializing in innovative solutions for punching, forming, and cutting metal parts. With a focus on quality, precision, and customer satisfaction, the company has established a reputation for excellence in the industry. Its comprehensive range of products and services caters to a diverse clientele across various industries.

High-Quality CNC Laser Cut Steel for Precision Manufacturing

The use of CNC laser cutting technology has revolutionized the steel fabrication industry, enabling companies to produce intricate and precise steel components with ease. One company at the forefront of this innovation is {Company Name}, a leading manufacturer of steel products. With a state-of-the-art facility and a commitment to quality and efficiency, {Company Name} has established itself as a trusted provider of CNC laser cut steel products.CNC laser cutting allows for the precise cutting of steel sheets and plates with the use of a high-powered laser. This technology is capable of cutting through various thicknesses of steel, making it an ideal solution for a wide range of applications. The precision of CNC laser cutting ensures that the finished components are accurately cut to the required specifications, with smooth edges and clean finishes.{Company Name} has invested significantly in CNC laser cutting technology, equipping their facility with the latest machinery to meet the growing demand for high-quality steel components. The company's team of skilled engineers and technicians are trained to operate the CNC laser cutting machines efficiently, ensuring that each product meets the highest standards of quality and precision.One of the key advantages of CNC laser cut steel is its versatility. The technology allows for the cutting of complex shapes and designs, making it suitable for a diverse range of industries, including construction, automotive, aerospace, and manufacturing. Whether it's producing intricate architectural elements, precision components for machinery, or structural steel beams, CNC laser cutting technology offers unparalleled flexibility and accuracy.In addition to its precision, CNC laser cutting also offers efficiency and cost-effectiveness. The automated process reduces material wastage and minimizes the need for secondary finishing processes, ultimately saving time and resources. This makes CNC laser cut steel an attractive option for businesses looking to optimize their production processes and maximize their return on investment.{Company Name} has leveraged CNC laser cutting technology to enhance its product offerings, providing customers with a wide range of steel components that meet their specific requirements. From custom-cut steel plates to intricate steel panels, the company has the capability to produce high-quality products in a timely manner, catering to the needs of various industries.Furthermore, {Company Name} is committed to upholding the highest standards of quality and safety in its manufacturing processes. The company adheres to strict quality control measures, ensuring that each CNC laser cut steel product meets the required specifications and complies with industry standards. Additionally, {Company Name} prioritizes the safety of its employees and the environment, implementing sustainable practices and safety protocols throughout its operations.As the demand for precision-engineered steel components continues to grow, {Company Name} remains dedicated to harnessing the power of CNC laser cutting technology to meet the needs of its customers. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to remain a leader in the steel fabrication industry, delivering top-notch products that uphold the highest standards of excellence.In conclusion, CNC laser cutting technology has significantly transformed the steel fabrication industry, enabling companies like {Company Name} to deliver precision-engineered steel components with unmatched accuracy and efficiency. With its investment in state-of-the-art machinery and a commitment to quality, {Company Name} continues to be a trusted provider of CNC laser cut steel products, meeting the diverse needs of its customers across various industries.

Top Turret Punch Companies: Unlocking the Power of Precision Sheet Metal Fabrication

Title: Turret Punch Companies Join Forces to Optimize Sheet Metal Fabrication SolutionsIntroduction:In a strategic move to leverage their respective expertise and enhance sheet metal fabrication solutions, two leading companies in the industry have recently merged their operations. The collaboration between [Turret Punch Company A] and [Turret Punch Company B] aims to revolutionize the way sheet metal components are produced, meeting evolving market demands efficiently. This partnership holds tremendous potential to drive technological advancements, streamline production capabilities, and ultimately provide customers with superior sheet metal fabrication services.Body:1. Background of Turret Punch Companies:[Turret Punch Company A] and [Turret Punch Company B] have long established themselves as pioneers in the sheet metal fabrication industry. Renowned for their commitment to precision engineering and reliable product quality, both companies have consistently pushed the boundaries of innovation. Their advanced turret punch presses and extensive experience in sheet metal processing have earned them accolades from clients across various sectors, ranging from automotive to aerospace.2. Synergy of Expertise:By merging their operations, [Turret Punch Company A] and [Turret Punch Company B] aim to combine their expertise and resources to offer customers a comprehensive suite of advanced solutions. The merger will pool together their research and development capabilities, allowing the newly formed entity to expedite the development and implementation of cutting-edge technologies in sheet metal fabrication. This synergy promises to revolutionize traditional manufacturing practices and maximize efficiency throughout the production process.3. Enhanced Production Capabilities:With the collaboration, the joint entity will have access to a wider range of turret punch presses, catering to a diverse set of customer requirements. These state-of-the-art machines are equipped with advanced features such as high-speed punching, automatic tool-changing, and precision control systems. Improved machine versatility and efficiency will enable the companies to handle complex sheet metal fabrication projects with greater precision and reduced lead times.4. Streamlined Operations and Supply Chain:The merger also brings the opportunity to streamline operations and optimize the supply chain. By leveraging their combined resources, [Turret Punch Company A] and [Turret Punch Company B] will consolidate their manufacturing facilities, leading to increased economies of scale. This consolidation will enhance their capabilities to handle large-scale production runs while maintaining stringent quality control measures. Additionally, a unified supply chain network will allow for easier sourcing of raw materials and reduce logistical complexities, enabling a seamless production process.5. Focus on Research and Development:One of the key objectives of the merger is to bolster research and development efforts. The joint entity will invest significantly in the advancement of automation technology, artificial intelligence, and machine learning algorithms to further enhance the efficiency of the turret punch presses. By automating various processes and incorporating intelligent control systems, the companies aim to minimize human error, reduce production cost, and deliver superior quality products.6. Customer-Centric Approach:Through this collaboration, [Turret Punch Company A] and [Turret Punch Company B] reiterate their commitment to providing exceptional customer service. The joint entity will leverage its expanded capabilities to offer customized solutions tailored to meet individual customer needs. By capitalizing on their combined expertise and resources, including a highly skilled workforce and an extensive distribution network, the companies aim to strengthen customer relationships further and ensure prompt delivery of high-quality sheet metal components.Conclusion:The merger between [Turret Punch Company A] and [Turret Punch Company B] is a significant development in the sheet metal fabrication industry. As a result of this strategic collaboration, the joint entity aims to enhance its technological capabilities, streamline production processes, and deliver superior offerings to clients. Their collective expertise and commitment to innovation positions them as industry leaders, capable of transforming the sheet metal fabrication landscape. This merger represents a step forward in providing efficient, state-of-the-art solutions for the evolving needs of customers in various industries.

CNC Cardboard Cutting Services in China: Fast and Efficient Solutions for Your Packaging Needs

China CNC Cardboard Cutting, a leading manufacturer in the packaging industry, has recently introduced a state-of-the-art cardboard cutting machine that is set to revolutionize the way cardboard packaging is produced. This cutting-edge technology is expected to significantly improve the efficiency and accuracy of cardboard cutting, ultimately leading to cost savings and higher quality packaging products.The new cardboard cutting machine is equipped with advanced CNC technology, which allows for precise and intricate cutting patterns to be achieved with minimal human intervention. This means that the machine is capable of producing highly customized and complex cardboard packaging designs, catering to the specific needs and requirements of each customer. With this capability, China CNC Cardboard Cutting is positioning itself as a pioneer in the packaging industry, offering a level of customization and quality that is unparalleled in the market.In addition to the unparalleled cutting precision, the new machine also boasts a high-speed cutting capability, significantly reducing lead times and increasing production capacity. This is particularly important for businesses in the packaging industry, where time is of the essence and quick turnaround times are crucial. By investing in this advanced technology, China CNC Cardboard Cutting is not only ensuring that its customers receive their orders in a timely manner, but also positioning itself as a reliable and efficient partner for businesses in need of high-quality cardboard packaging solutions.Furthermore, the new cardboard cutting machine is also equipped with a user-friendly interface, making it easy for operators to program cutting patterns and operate the machine with minimal training. This ensures that the machine can be integrated seamlessly into existing production processes, minimizing downtime and maximizing productivity. Additionally, the machine is designed with safety features to ensure the well-being of operators, adhering to the highest industry standards for workplace safety.With the introduction of this new cardboard cutting machine, China CNC Cardboard Cutting is poised to gain a competitive edge in the packaging industry. By offering an unparalleled level of customization, precision, and efficiency, the company is well-positioned to attract new customers and retain existing ones. In an industry where packaging plays a crucial role in branding and product presentation, the ability to offer highly customized and high-quality packaging solutions is a significant competitive advantage.As a company, China CNC Cardboard Cutting has a proven track record of delivering innovative and high-quality packaging solutions to its customers. With a focus on research and development, the company has consistently invested in cutting-edge technology to stay ahead of the competition and meet the evolving needs of the market. The introduction of the new cardboard cutting machine is a testament to the company's commitment to innovation and excellence, and is expected to further solidify its position as a leader in the packaging industry.Moreover, China CNC Cardboard Cutting is not only dedicated to delivering high-quality products, but also to providing exceptional customer service. The company prides itself on building long-lasting relationships with its customers, working closely with them to understand their unique packaging needs and delivering tailored solutions that exceed their expectations. With a team of dedicated professionals and a customer-centric approach, China CNC Cardboard Cutting has earned a reputation as a trusted and reliable partner in the packaging industry.In conclusion, the introduction of the new cardboard cutting machine by China CNC Cardboard Cutting represents a significant milestone for the company and the packaging industry as a whole. With its advanced CNC technology, high-speed cutting capability, user-friendly interface, and commitment to customer satisfaction, the company is well-positioned to set new standards for cardboard packaging production. As businesses continue to demand highly customized and high-quality packaging solutions, China CNC Cardboard Cutting is poised to meet and exceed these expectations, driving innovation and excellence in the packaging industry.

High Precision Cnc Punch Machine for Sheet Metal Fabrication

The CNC Punch Machine is revolutionizing the sheet metal manufacturing industry with its advanced technology and precision engineering. This machine, produced by a leading sheet metal fabrication company, has quickly become a game changer in the industry due to its innovative features and unparalleled performance.With the increasing demand for high-quality sheet metal products, manufacturers are constantly seeking ways to improve their production processes. The CNC Punch Machine is a highly efficient and versatile solution that is designed to meet the complex demands of modern manufacturing.One of the key features of the CNC Punch Machine is its advanced CNC control system, which allows for precise and rapid punching of various shapes and sizes on sheet metal. This level of precision is crucial for industries such as automotive, aerospace, and electronics, where tight tolerances and complex designs are the norm.The machine is also equipped with a high-speed servo hydraulic punching head, which provides the necessary force to punch through thick sheet metal with ease. This ensures that the machine can handle a wide range of materials, including stainless steel, aluminum, and copper, making it a highly versatile solution for manufacturers.In addition to its impressive punching capabilities, the CNC Punch Machine is also equipped with advanced automation features that streamline the production process. The machine is integrated with a material handling system and a robotic tool changer, which allows for seamless loading and unloading of materials and tools. This efficient automation not only reduces manual labor and human error but also significantly improves overall productivity.Furthermore, the CNC Punch Machine is designed for flexibility, with the ability to be easily programmed for different punching patterns and tool configurations. This means that manufacturers can quickly adapt to changing production needs and produce a wide range of products without the need for complex retooling or setup.The reliability and durability of the CNC Punch Machine are also noteworthy. It is constructed with heavy-duty components and a robust frame, ensuring that it can withstand the rigors of continuous operation in a demanding manufacturing environment. This level of durability, combined with regular maintenance and support from the manufacturer, ensures that the machine delivers consistent performance over the long term.The introduction of the CNC Punch Machine has significantly raised the bar for sheet metal manufacturing, providing manufacturers with a cutting-edge solution that combines precision, speed, and versatility. As the demand for high-quality sheet metal products continues to grow, it is clear that this innovative machine will play a key role in shaping the future of the industry.In conclusion, the CNC Punch Machine is a game-changing technology in the sheet metal manufacturing industry, offering unmatched precision, versatility, and efficiency. As manufacturers continue to seek ways to improve their production processes, this advanced machine is sure to become an indispensable asset in delivering high-quality sheet metal products to meet the demands of various industries. With its advanced features and proven performance, the CNC Punch Machine is paving the way for the future of sheet metal manufacturing.

Top 5 Advantages of CNC Laser Cutting Services in China

China CNC Laser Cutting, a leading company in the field of precision laser cutting, has once again proven its dedication to excellence with its latest technological advancements. The company, which has been at the forefront of innovation for over a decade, has consistently delivered high-quality products and services to its clients in the fields of automotive, aerospace, electronics, and many others.The recent addition of state-of-the-art [Brand Name] laser cutting machines has further enhanced the capabilities of China CNC Laser Cutting, allowing them to offer even more precise and efficient cutting solutions to their customers. These machines, equipped with the latest technology and cutting-edge features, are capable of handling a wide range of materials, including steel, aluminum, copper, and various alloys, with unparalleled accuracy and speed.In addition to their cutting-edge machinery, China CNC Laser Cutting has a team of highly skilled engineers and technicians who are experts in the field of laser cutting and are committed to delivering top-notch results. With their expertise and the cutting-edge technology at their disposal, the company is able to offer a wide range of services, including laser cutting, welding, and fabrication, all of which adhere to the highest industry standards.One of the key advantages of choosing China CNC Laser Cutting as a partner is their commitment to quality and precision. The company has invested heavily in their quality control processes, ensuring that every product that leaves their facility meets the strictest quality standards. This dedication to quality has earned them a reputation as a trusted and reliable partner for companies looking for precision cutting solutions.Moreover, China CNC Laser Cutting is dedicated to staying ahead of the curve when it comes to technological advancements. They regularly invest in research and development to ensure that they are always at the forefront of the industry, offering their clients the most advanced and efficient cutting solutions available. This commitment to innovation has allowed them to maintain their position as a leader in the field and has earned them the trust and loyalty of their clients.In addition to their technical expertise, China CNC Laser Cutting is also known for their excellent customer service. The company takes great pride in providing personalized solutions to meet the specific needs of their clients, working closely with them to ensure that the final product meets and exceeds their expectations. This dedication to customer satisfaction has earned them a loyal customer base and has set them apart as a preferred partner in the industry.Looking ahead, China CNC Laser Cutting is poised to continue its legacy of excellence in the field of precision laser cutting. With their cutting-edge technology, skilled team, and commitment to quality and innovation, the company is well-positioned to meet the evolving needs of their clients and to remain a leader in the industry for years to come.In conclusion, China CNC Laser Cutting is a company that exemplifies excellence in the field of precision laser cutting. With their advanced technology, skilled team, and commitment to quality and innovation, they have set themselves apart as a trusted and reliable partner for companies in a wide range of industries. As they continue to invest in their capabilities and stay ahead of the curve in terms of technological advancements, they are well-positioned to maintain their leadership position in the industry and continue to deliver exceptional results for their clients.

Affordable and Efficient CNC Fiber Laser Machines to Boost Your Business

Title: Cutting-Edge Cheap CNC Fiber Laser Factory Revolutionizes Manufacturing IndustryIntroduction:In a groundbreaking development, a renowned CNC fiber laser manufacturer has emerged as a pioneer in the field of affordable and cutting-edge laser machinery. This company, whose identity we cannot disclose due to brand name restrictions, has revolutionized the manufacturing industry with its cost-effective and efficient solutions. Combining advanced technology with unmatched precision, this cheap CNC fiber laser factory is setting new standards in the market. This news article delves into the company's background and highlights its contributions to the manufacturing sector.Company Background:Established several decades ago, this CNC fiber laser manufacturer has gained a solid reputation for producing high-quality and reliable laser machinery. Their commitment to innovation has allowed them to stay ahead in an ever-evolving industry. The company prides itself on its ability to design and manufacture laser cutting and engraving machines that are not only affordable but also deliver outstanding performance. They cater to a diverse range of industries, including automotive, aerospace, electronics, and signage.Key Features of the CNC Fiber Laser Factory:1. Advanced Technology:The cheap CNC fiber laser factory is equipped with state-of-the-art technology that ensures optimal performance and accuracy. The integration of fiber laser technology enhances the cutting and engraving capabilities, providing precise and intricate results. Advanced software enables seamless operation and compatibility with various design formats.2. Cost-Effective Solutions:Unlike many competitors, this manufacturer recognizes the importance of affordability. Their laser machinery offers cost-effective solutions without compromising on quality. By optimizing the manufacturing processes, they manage to reduce the overall costs while maintaining high precision and reliability. This ensures that even smaller businesses can benefit from the advantages of CNC fiber laser technology.3. Customizable Options:Understanding the diverse needs of their clientele, this cheap CNC fiber laser factory provides customizable options to suit specific requirements. Customers can choose from different power levels, bed sizes, and additional features based on their production demands. The company's flexibility in catering to individual needs sets them apart from their peers.4. Extensive Application Range:The laser machinery produced by this manufacturer finds extensive applications across various industries. Organizations can utilize these advanced tools for cutting and engraving different materials ranging from metals and plastics to wood and ceramics. The CNC fiber laser factory's versatility allows customers to expand their production capabilities and explore new business opportunities.5. Superior Customer Support:Aside from providing superior products, the company ensures excellent customer support throughout the buying process and beyond. Their dedicated team of experts offers comprehensive training, guidance, and prompt technical assistance, ensuring a smooth transition to utilizing CNC fiber laser machinery.Conclusion:This groundbreaking CNC fiber laser factory, which we are unable to publicly reveal due to brand name restrictions, is revolutionizing the manufacturing industry. By combining cutting-edge technology, cost-effective solutions, and extensive customization, this manufacturer stands out among its competitors. The affordability and precision of their laser machinery open up new possibilities for businesses of all sizes, allowing them to enhance productivity and explore uncharted territories. With the cheap CNC fiber laser factory's superior customer support and dedication to innovation, the future of manufacturing looks promising.

Top Factory Offers High-Quality CNC Pressbrakes for Professional Metalworking" can be rewritten as "Get High-Quality CNC Pressbrakes for Professional Metalworking from a Top Factory".

Title: Leading CNC Press Brake Manufacturer Revolutionizing the Metalworking IndustrySubtitle: Advanced Technology, Precision, and Customization Define New Benchmark [City, Region] - In an era of rapid industrialization and technological advancement, {Company Name}, a renowned CNC press brake manufacturing company, is setting new industry standards with its state-of-the-art solutions. With a relentless commitment to innovation, precision, and customer satisfaction, {Company Name} is pushing the boundaries of what is possible in the metalworking sector.With a rich history spanning over [X] years, {Company Name} has achieved exponential growth and has become a globally recognized leader in the field. Their cutting-edge press brake machines cater to various industries, including automotive, aerospace, energy, and construction. By adhering to stringent quality standards and integrating the latest technologies, {Company Name} continues to elevate productivity, efficiency, and accuracy for its diverse clientele.One of the key distinguishing factors behind {Company Name}'s success is its state-of-the-art manufacturing facility. Equipped with advanced machinery and computer-controlled processes, the factory floor showcases the perfect amalgamation of human expertise and robotic precision. Highly trained engineers and technicians work side by side with cutting-edge automated systems, ensuring the highest levels of quality control and consistency throughout the production process.Recognizing the evolving needs of modern metal fabricators, {Company Name} embraces a customer-centric approach. They understand that each industry has its unique requirements and strive to deliver tailored solutions. Customization is at the heart of their business ethos, allowing clients to select from a wide range of features, such as bending force, working length, and sophisticated controls, to create a press brake machine that best fits their specific needs.Investing heavily in research and development, {Company Name} is at the forefront of technological advancements in the sector. Their dedicated team of engineers continually explores new manufacturing methodologies, materials, and software integration to deliver cutting-edge press brake solutions. The company's commitment to innovation is evident in their adoption of Industry 4.0 principles, incorporating IoT connectivity, artificial intelligence, and data analytics to enhance performance and productivity.The value proposition that sets {Company Name} apart from its competitors lies in its uncompromising focus on precision. Every press brake machine undergoes rigorous testing and quality checks to ensure it meets the highest standards. By leveraging the advancements in robotics and artificial intelligence, {Company Name} optimizes accuracy, repeatability, and speed, delivering unparalleled precision in every bend.Beyond their commitment to crafting exceptional machines, {Company Name} also excels in providing comprehensive after-sales support. Recognizing the importance of uninterrupted operations for their clients, they offer prompt service and maintenance programs, including remote diagnostic capabilities and on-site repairs. The company's dedicated team of skilled technicians ensures quick response times, minimizing downtime for their customers.{Company Name} is also committed to sustainability and reducing its environmental footprint. By implementing energy-efficient processes, waste reduction practices, and responsible sourcing of materials, they are working towards creating a greener and more sustainable metalworking industry for future generations.In conclusion, {Company Name} continues to shape the metalworking landscape with its cutting-edge CNC press brake machines. By combining advanced technology, customization options, and an unwavering commitment to precision, the company remains a trusted name in the industry. With its state-of-the-art manufacturing facility, customer-centric approach, and dedication to continuous innovation, {Company Name} sets the benchmark for excellence in the manufacturing of press brake machines globally.